Hongwen holds two yarn manufacturing enterprises: Hangzhou Banglian Spandex Co., Ltd. and Zhejiang Lianhong Fiber Technology Co., Ltd. Among them, Banglian mainly produces spandex yarn. Since its establishment, the company has given full play to the institutional advantages of private enterprises, continuously promoted technological innovation and management innovation, which achieved high-efficiency and low-cost expansion. At present, it can produce spandex yarns of different specifications of 10D-1120D, such as matte, semi-matte, glossy, chlorine-resistant, and high-temperature resistant. It is widely used in warp-knitted, weft-knitted, woven, pantyhose and other fabrics. Product performance, last time efficiency and profitability are among the forefront of the domestic industry. It mainly produces various fibers: open spinning, siro spinning, compact siro spinning and various specifications of nylon spandex covered yarn. Lianhong always attaches equal importance to technological innovation and management innovation, and attaches importance to brand management and talent building. Now the company has 2 invention patents, 17 utility model patents, several provincial-level new products, and 1 municipal-level R&D center.

Hongwen Fabric

Hongwen has a full range of production capacity covering knitting and weaving. We have 220 Taiwan Bushuo large circular knitting machines, 3000 Tsudakoma air jet looms and 1,000 Toyota water jet looms. The company continues to explore, persists in innovation, and unswervingly follows the path of industrial diversification, creating a giant aircraft carrier from spinning to weaving. Woven fabrics are mainly Four-way stretch fabric, grosgrain, TR stretch cloth, corduroy, etc.; knitted fabrics are mainly rayon jersey, NR, TR series Roman cloth, air layer, suede, etc. In 2020, the company continued to research and develop innovative materials, including Tianxi, Modale, copper ammonia, DuPont N66 imitation cotton yarn products for sports and leisure, sweat-absorbing functional fabrics and environment-friendly yarn.

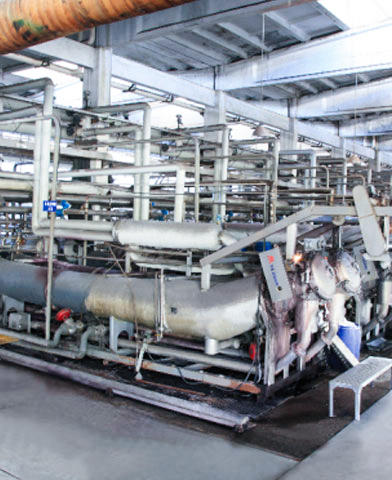

Hongwen Printing and Dyeing

Hongwen built a new dyeing factory, specializing in textile printing and dyeing processing business, which is committed to providing customers with professional, integrated and personalized comprehensive printing and dyeing services, mainly including two series of knitted fabric printing and dyeing and woven fabric printing and dyeing.The company's printing and dyeing business is commissioned by customers. The customer provides the grey fabric, and the company performs customized printing and dyeing treatment on the grey fabric according to the customer's requirements. The main process includes pre-treatment, dyeing, finishing and other technological links. The textile fabrics after printing and dying are widely used in the fields of casual clothing, sportswear and business formal wear.Since its establishment, Hongwen has been committed to building an energy-saving, environmentally-friendly and intelligent manufacturing printing and dyeing enterprise with the tenet of technological innovation and green environmental protection, constantly improving management and service quality.

Hongwen Home Textiles

In order to better develop and expand the industrial chain, Hongwen has reached a strategic cooperation with Hangzhou Jiuji, rebuilding the factory, and supplying home textiles and toys for Jiuji. Hangzhou Jiuji Holding Co., Ltd. is located on the bank of the beautiful West Lake—Hangzhou. Established in 1998 , the company was the first production-oriented Japanese enterprise to settle in Binjiang High-tech Zone. After more than 20 years of development, the company has gradually formed its own unique brand advantage in the home textile industry. Through product innovation, market globalization, and new retail integration, the company has completed transformation and upgrading from a production-oriented enterprise, growing into a modern fast-moving consumer goods manufacturing enterprise integrating product planning, design, production and global trade.

-

The whole process

Quality Control

In 2020, the company will expand its production scale: it has invested 1 billion yuan to build Xinjiang Zhongtai Haihong textile printing and dyeing Co., Ltd., which is mainly engaged in the R & D and production of various kinds of cotton yarn, rayon yarn, chemical fiber, air-jet and knitted fabrics. The company constantly explores, adheres to innovation, unswervingly takes the road of industrial diversification, and creates a huge aircraft carrier from spinning to weaving.

-

Daily production of yarn: 500 tons

-

Daily production of woven fabrics: 1 million meters

-

Daily production of knitted fabrics: 80 tons

-

Printing and dyeing: annual output of 330 million meters of woven fabrics and 33,000 tons of knitted fabrics