In recent years, with the continuous expansion of the company’s production scale and increasing capacity, the high-end market both at home and abroad have proposed that high standards should be set for yarn to maintain its high quality. Meanwhile, the production process, equipment and technology management should be improved and innovated. Therefore, quality control is of great critical, which asks us to attach high importance to quality while considering production cost. The textile industry we are engaged in is highly competitive, so in the current environment of global financial crisis, the only way to success is adhering to quality first, improving competitiveness, making products suitable and satisfying for customers and cultivating excellent enterprise brand.

Process quality management regulations

-

1

Organizational process of enterprise production process quality management

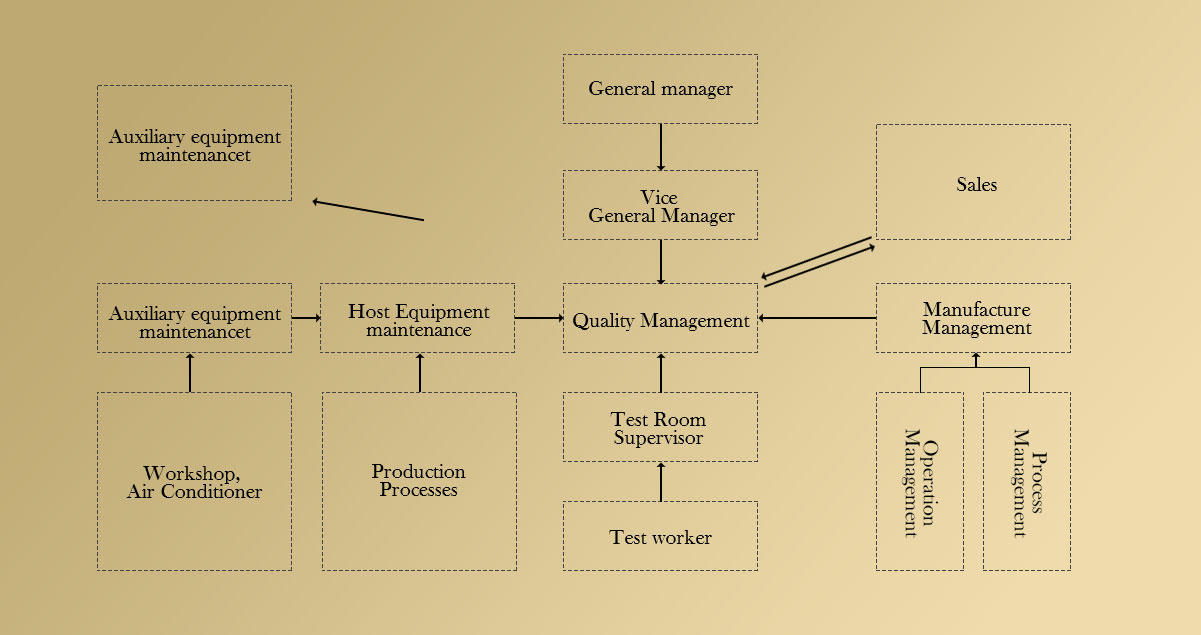

1. Organization chart of enterprise production process quality management

2. From the above structure chart, all work should be focused on quality: Equipment maintenance must be conducted on the premise of stable quality. The setting of process parameters and operation adjustment of the production department must ensure quality stability. The goal of quality is to meet the market and customers’ requirements, as our products are manufactured for the customers instead of our own, so it will cause a big loss if no customer buy our products.

-

2

Process quality management based on customers’ requirements-continuously stable product quality

1. Quality control is started from raw material and ended by the final product. So the quality control department manager is required to be experienced from the raw materials to the whole production process. Any production and equipment changes must be communicated with the Quality Control Manager and confirmed by the QC Manager, so they will make a work plan in order to ensure the stable quality of the products. If the quality index of each process exceeds the scope, the equipment personnel must be informed to conduct inspection and maintenance, establishing the “quality first” concept.

2. The quality management department is the centralized department of product quality, which decides on the quality of the finished products. Adjustment in the production process, such as the replacement of textile equipment needs to be negotiated with the quality control department, other departments (such as production department) should cooperate with the quality management department. Most importantly, the leaders of production, equipment and quality department must be united and cooperative with timely communication to ensure stability of product quality.

3. The quality control department is the quality management of the whole enterprise, so each workshop must equipped with its own quality inspection personnel, who is responsible for the quality work of each workshop and reports the problems found to the quality control department manager in time.

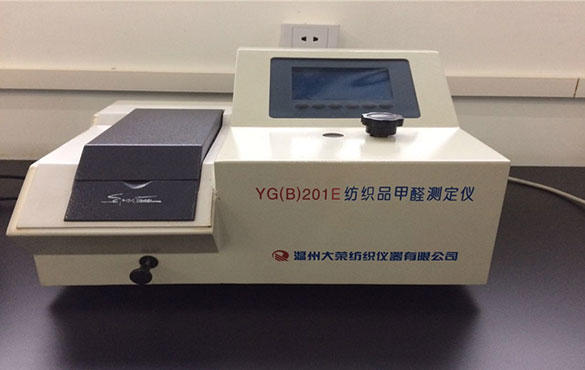

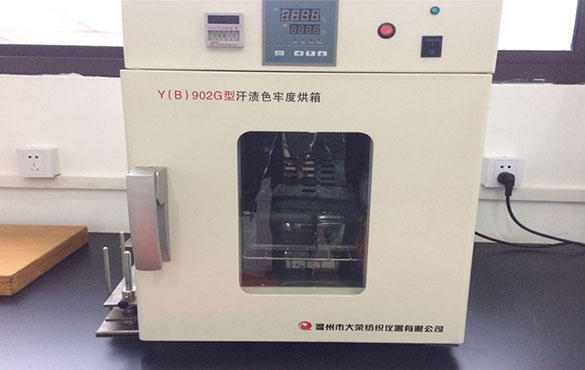

4. The quality core of the whole enterprise is the test room. The testers should have a high sense of responsibility and be responsible for quality. The process can not be changed at will without confirmation by the quality data of the test room. The test results should be properly preserved to make comparative analysis for further work. Enterprises should establish our own database to monitor the quality and guide the improvement of the process. The environment, temperature and humidity of the test room shall be stable to meet the test requirements.

5. Quality assurance department should communicate with Sales department to discuss how to best meet customers’ requirements and the handling of customer claims and complaints with the consent of corporate executives.

-

3

Basic management is the key to ensure quality. First-class product quality must be supported by first-class basic management.

1. Raw materials are the guarantee of product quality. So the raw materials into the factory should be strictly checked, quality index of all kinds of raw material should be prescribed, and the content of three yarn in the raw cotton yarn should be strictly controlled.

2. Process research should be improved, textile special equipment should be well selected, and the stability and consistency of product quality should be pursued. The management of textile equipment is upgraded to process management while optimizing the process, focusing on the optimization of textile equipment and the quality inspection when products flow into the factory, which is equipped with a variety of textile equipment inspection tools in order to do the inspection to all the textile special equipment bought one by one to find unqualified for return, if the unqualified rate is too high, purchase must be stopped and the manufacturer will be replaced. Changing textile special equipment by varieties and regions to ensure the consistency of equipment from the use time.

3. Improving the operation management and eliminating the abnormal quality fluctuations caused by operation. The cotton strips are not wrapped front to back and the yarn does not knot, using the one piece to the end and non-critical operation mode.

-

4

Quality control is like a pyramid, great attention should be attached from top to bottom. So quality control organization is a pyramid shape, for the upper management concept must be implemented to the bottom of the management so that everyone can got the idea. It is easy to produce defects in the production process, so we need to focus on the details, integrating the concept of improving product quality into everyone's behavior, making it a conscious action to maintain long-term stable work quality, so as to ensure that the quality monitoring of the whole process of products from fiber to yarn products come true. Enterprise always put quality into the first place, and high quality needs to based on consistency. The quality control department is the key department, the quality control personnel and the equipment maintenance personnel communicate with each other, and the maintenance personnel should be supervised by the quality controller. Quality control personnel and sales will communicate in time to acknowledge customers’ feedback. In the production process, monitor production should in line with test data to maintain quality stability and improve product quality. The products produced are at expensive cost, requiring every employee to realize that every small flaw and mistake will cause losses to the enterprise.

-

5

Establish a data analysis and management system, using the chart to control the quality of the whole production process. We should not only have a good average quality, but also need to stabilize this good quality for a long term. With a large number of test data, relevant departments should analyze whether the quality data meets the standard requirements, what measures should be taken and draw conclusions based on the quality report data of the process.

-

6

Enterprises should sort out and improve the process quality management system of the textile industry. As a traditional industry, the basic management system documents are relatively complete, so we need to keep pace with the times according to the constantly picky customers and market. At the same time, the process quality management system should be constantly supplemented, standardized and improved for strictly implement.

1. 1、System, strictly enforce process discipline. The process adjustment and new products manufacture shall be implemented according to the three-level approval requirements and the process plan based on product quality should be constantly optimized.

2. 2、Formulate the Raw Material Management System, and make further criterion to the procurement standards of raw materials, incoming inspection, cotton distribution, and the management of suppliers.

3. Establish the Quality Management System of Textile Equipment, configure the inspection tools of each textile equipment according to the quality standard requirements of the manufacturers, strictly check the textile equipment when it comes into the factory, and implement the management of the suppliers.

4. Revised the Quality Testing Plan for Semi-finished Products and Finished Products, sort out all the test items of each process, and shorten the test period of key quality indicators so as to master the quality changes and take corresponding measures to improve them.

5. Improve the Process Quality Standard, Early Warning and Car Closure Management System, the quality control department is responsible for the formulation of internal control indicators of each production process, launch new products according to raw materials, process, season, customer demand and varieties.